Heat 2 Power-Engine [ ]

]

Useful work: Steady-state temperature profile with high temperature differences

- The entire Heat2Power system operates with steady-state temperature conditions – no cyclic heating/cooling of components.

- The expansion cylinders are always supplied with the hottest portion of the gas from the regenerator, the compression cylinders with the coldest.

- No thermal shocks and no feedback losses – this increases mechanical stability and service life.

- Stable temperature control allows the use of high-strength materials without fluctuating loads.

Show more technical details

Unlike classic Stirling engines with constantly changing temperature conditions, the entire Heat2Power system operates with a stable thermal profile. The temperature gradient between the hot and cold sides remains constant, enabling a highly efficient design. Instead of theoretical isotherms, the concept relies on realistic thermodynamic processes, allowing for an approach to physical limits.

The working gas is additionally cooled in the low-pressure line before entering the cylinders, making it particularly easy to achieve low temperatures here.

The result: maximum internal heat recovery, high efficiency, lower material stresses and a significantly extended service life with stable process control.

Efficient recuperator

- The counterflow principle in the regenerator replaces the pulsating pendulum flow of classic Stirling engines and generates extremely high temperature differences between the inlet and outlet sides.

- The recuperator can be dimensioned to any size – without any dead space. It contains significantly more working gas than is the case with conventional engines.

- The longer residence time of the working gas in the recuperator ensures maximum internal heat recovery.

- The cylinders switch continuously – this enables a continuous gas flow with consistent turbulence for efficient heat transfer.

- The high heat recovery rate reduces external energy consumption and significantly improves the overall energy balance.

Show more technical details

The recuperator is designed as a tube bundle, with the high-pressure flow passing through the tube side – this keeps pressure losses low and the mechanical design easily manageable.

The low-pressure flow passes through the shell; the shell therefore only needs to be designed for the low-pressure flow, reducing material and manufacturing costs.

The flow is consistently counterflow; turbulent conditions are deliberately created via geometry and flow velocity, without cyclic reversals.

The tube side can be made of smooth or structured tubes (e.g., internally ribbed) to optimize heat transfer, while the shell is baffle-guided (segmented) for defined cross-sectional velocities.

Material selection follows the temperature side: high-temperature-resistant steels on the hot tube side; cost-effective grades on the cool shell side. This ensures that critical components remain thermally and mechanically decoupled.

Scaling is achieved via the number of tubes, tube length, and shell diameter; the overall size is not limited by dead volumes. Design criteria include pressure loss budgets, target NTU, and permissible temperature approximation.

The continuous gas flow keeps the turbulence constant over time, preventing cyclical drops in the effective heat transfer coefficient and maximizing internal heat recovery.

Optimized equipment requirements

- The Heat2Power-Engine is an impressively simple design, relying on a clear, modular structure with just a few core components.

- The amount of equipment required is minimal – without complex auxiliary components such as turbochargers, valve trains, or elaborate cooling circuits.

- Components are geometrically simple, modular in design, and therefore easy to manufacture, maintain, and scale.

-

The

Hypocycloid Gear

replaces the classic crankshaft and ensures precise, low-loss movement of the pistons.

replaces the classic crankshaft and ensures precise, low-loss movement of the pistons.

- A simple internal mechanism handles the basic control functions – robust, low-maintenance and free from complicated devices.

Show more technical details

The Heat2Power engine utilizes a hypocycloid gear that replaces the conventional crankshaft, enabling linear piston guidance with minimal lateral forces.

This significantly reduces friction losses, allowing for a particularly flat piston geometry.

The internal mechanics are deliberately kept simple – without complex valve trains or external control elements.

All assemblies are modular and can be dimensioned or replaced independently.

Even at high temperatures, the mechanics remain stable, as no active cooling or lubrication is required.

These design simplifications result in high reliability and facilitate scaling up to power outputs exceeding 10 MW.

Versatility and variability

- The Heat2Power-Engine can utilize any suitable central heat source – from industrial waste heat and landfill gas to surplus power from renewable energy generation.

- The system is flexibly convertible to various fuel types (e.g., Diesel, bio-LNG, H2) and is therefore ideal for maritime and industrial applications.

- For higher efficiency, an additional recuperator can be connected in series – without fundamental system modifications.

- This high degree of variability makes the system a key component of the energy transition: Direct reconversion of waste heat into electricity, decentralized backup power plants during periods of low wind and solar power generation, and smoothing and reconversion of surplus power using high-temperature thermal storage systems.

Show more technical details

Fuel and source neutrality: The heat source only feeds the hot circuit; the internal process remains unchanged.

Storage integration: Coupling with high-temperature storage systems enables medium storage durations and stable continuous load provision.

Peripheral options: The recuperator and cooler are freely scalable (number of tubes, length, shell diameter) without dead volume limitations.

Installation flexibility: Separate modules facilitate placement in existing systems, including separate media paths and maintenance zones.

Efficient heat transfer

- Heaters and coolers are located directly in the gas circuit lines – their size and therefore their efficiency is not limited by the design of the cylinder head.

- Heat input directly into the high-pressure pipeline using integrated devices or

Heat Pipes

enable particularly low-loss heat transfer – even at temperatures above 1000K. Heat pipes placed directly on the cylinder walls can also be used to stabilize the temperature during expansion.

enable particularly low-loss heat transfer – even at temperatures above 1000K. Heat pipes placed directly on the cylinder walls can also be used to stabilize the temperature during expansion.

Show further technical explanations

Positioning the heater and cooler outside the cylinder allows for flexible designs – for example, with integrated shell-and-tube heat exchangers and external heat pipes. Thanks to the steady-state operation, no thermal fluctuations occur.

The cold side can even be cooled below ambient temperature through recompression and intelligent cooling.

Thermodynamic efficiency:

- The Heat2Power-Technology is based on a modified Stirling process. It does not utilize strict isothermal state changes, but realistic thermodynamical processes with higher pressure changes and reduced heat exchange.

- This significantly increases the useful work output per cycle – without transferring large amounts of heat between components.

- The theoretical process states in the pV diagram are almost fully utilized, and the extreme points of the pV diagram are driven more effectively.

- There is practically no overlap between the four operating cycles – each change of state is clearly defined.

- The amount of gas heated or cooled corresponds to the amount expanded or compressed – no mixed temperature profile as in classic Stirling engines.

- The compression ratio is significantly higher than in conventional Stirling engines, resulting in considerably more useful work and increased power density – up to a factor of 3 compared to classic Stirling engines, and over 10% to 50% compared to Diesel/Otto engines.

Mathematical basis: Formula and parameters

The work W gained per cycle depends significantly on the compression ratio and temperature difference.

For context: The following approximation formula results for an idealized isothermal process:

$$W_\text{iso} = n \cdot R \cdot \ln\left(\frac{V_\text{max}}{V_\text{min}}\right) \cdot \left(T_\text{max} - T_\text{min}\right)$$

With:–

n: Number of moles–

R: Gas constant–

Vmax/Vmin: Compression ratio–

Tmax – Tmin: Temperature difference hot / cold➡ This formula shows that any increase in the compression rate

ln(Vmax/Vmin) or the temperature range significantly increases the work gained.The Heat2Power engine, however, does not use strictly isothermal but realistic changes of state – with a significantly higher pressure ratio and without cyclic heat exchange.

This allows for better utilization of the theoretically usable area in the pV diagram, and the actual gained work output significantly exceeds that of classic Stirling engines.

➡ In practice, this type of process control allows for higher power density and efficiency – with simultaneously reduced losses and stable temperature control.

Comparison: Performance increase through compression

Typical compression ratios:

– Classic Stirling engine: approx. 2–3

– Gasoline engine: approx. 9

– Diesel engine: approx. 22

– Heat2Power-Engine: up to ≥30 → significantly higher power density

Example values for ln(Vmax/Vmin):

ln(30) ≈ 3.40 ln(22) ≈ 3.09 ln(9) ≈ 2.19 ln(3) ≈ 1.09

➡ With a achievable ratio of, for example, 30, the Heat2Power engine achieves three times the useful work compared to classic Stirling engines. Double-acting cylinders further increase the power density – by a factor of 6 compared to single-acting engines.

System technical implementation

In the Heat2Power-Engine technology, the state changes (expansion, compression, isochoric heating/cooling) occur sequentially at different locations within the system. They happen sequentially and without overlap or mixing.

By sealing the cylinders and minimizing dead spaces, the amount of gas heated/cooled corresponds exactly to the amount expanded/compressed. In contrast, in conventional Stirling engines, a large portion of the enclosed gas mass remains thermally inactive – although it is compressed and expanded, it contributes very little to the power output, as the expansion/compression propagates uselessly into the regenerator.

One crankshaft revolution in the Heat2Power-Engine already results in two power strokes. Therefore, a single pair of cylinders replaces a conventional V8 gasoline, diesel, or marine engine with 4–8 cylinders for the same number of cycles.

➡ Result: Significantly higher thermodynamic efficiency.

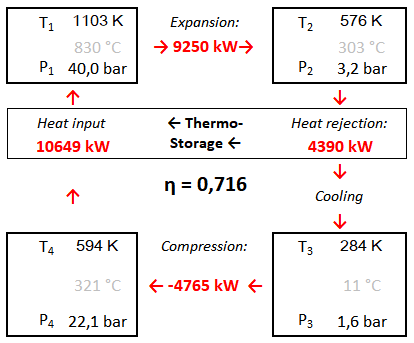

Example: Thermal efficiency calculation

Example of a calculation for a system with approximately 4400 kW (8 cylinder pairs with a total displacement of 550 liters, 500 rpm). The calculation already includes pressure losses in the pipelines and friction losses. It is based on a detailed, segmented calculation of expansion and compression, taking into account realistic pipe lengths, internal components, bends, etc., in conjunction with a thermal storage tank with 8x12 modules, a convection cooler and an absorption cooler between the thermal storage tank and the compression cylinder.

Low internal losses:

- Generous pipe cross-sections enable low flow resistance, even in the regenerator.

- Scavenging and charge exchange losses, as seen in the valve trains of conventional combustion engines, are minimal.

- Cylinder chambers are filled and emptied via short paths, large flow cross-sections, and with minimal pressure loss.

- Unlike other machines, significant power is not diverted to operate auxiliary components (turbocharger, water pump, valve train, etc.).

Show more technical details

The pipelines are fully flow-active – they have no dead space and can therefore be designed with a large cross-section. This reduces flow resistance.

Unlike gasoline or diesel engines, there are no charge exchange losses. Due to the short path and precise control inside the piston rod, the working gas is efficiently guided and cannot be lost.

Reduction of heat loss:

- Both cylinder chambers have the same wall temperature – there is no heat flow between the hot and cold sides.

- There is no mutual heating or cooling through shared pipes; unlike in a standard engine, the working gas does not carry heat away from the working cylinder through heated pipes during the exhaust stroke.

- Waste heat is not released via the exhaust gas – it remains in the system and is reused.

- Two chambers share one cylinder – this halves the wall heat losses compared to single-acting engines.

- Optional use of

Heat Pipes

can minimize the temperature loss between the heat source and the gas.

can minimize the temperature loss between the heat source and the gas. - All components are insulated – heat losses occur only on one side of the system.

- No cast engine block with a large radiating surface – minimal radiative losses.

Show more technical details

In conventional engines, heat flows from the hot to the cold part of the cylinder, especially when the piston moves cyclically between these areas. In the Heat2Power-Engine, both chambers have identical wall temperatures – thus eliminating internal heat flow and thermal displacement.

Heat losses at the wall surface are reduced by split cylinders (two chambers per block). The surface area per chamber is smaller than in single-acting engines, also due to the flat piston – this halves heat conduction losses.

Heat pipes enable a low-loss connection between the external heat source and the gas circuit. They require no moving parts and do not generate their own flow – this reduces heat loss to a minimum.

Wear

- Pistons do not serve as an external seal – they operate with a small gap to the cylinder wall.

- The piston rod is guided outside the cylinder chambers – i.e., outside the hottest areas.

- Little or no lubrication is necessary – e.g., through the use of plastic plain bearings.

- Oil-free operation of the compression cylinders is possible.

- Very few sealing points – and only outside the hottest areas.

- Short pistons, hollow piston rods and low rotational speeds → low inertial forces.

- Gas buffer at the end of the cycle and low rotational speed → reduced inertial forces.

- Linear arrangement of the cylinders (boxer engine) ensures pressure peak compensation – dead centers cancel each other out.

Show more technical details about the mechanics

The pistons do not seal against the crankcase and do not require a conventional oil passage. This means that lubricants can be largely dispensed with – especially in cold conditions.

Compression cylinders can be equipped with durable polymer bearings such as Iglidur W300©.

Low rotational speeds (approx. 200–600 rpm) and short, lightweight pistons minimize inertial forces. Hollow piston rods further reduce the moving mass. At the end of the power stroke, a gas buffer, combined with the low rotational speed, reduces the load from inertial forces.

The linear "boxer" configuration (an opposing cylinder arrangement) ensures mechanical balance: pressure peaks occur simultaneously and cancel each other out. This keeps the bearings and pistons mechanically relieved of stress.

Show more technical details on thermodynamics

– Adiabatic Expansion (n = κ): steep pressure curve with a high pressure difference.

– Isothermal Expansion (n = 1): flatter pressure curve.

Low friction losses

- No lateral forces act on the pistons – resulting in low friction and no need for guide seals.

- Flat piston geometry in the double-acting cylinders → only two piston rings per double-acting cylinder pair (= four chambers) are required.

- Piston rings do not serve as an external seal – a minimal gap and low contact pressure are sufficient.

- Gas sealing is concentrated in the piston rod areas – only there do significant friction losses occur.

- Leakage flows occur exclusively on the crankshaft side – a maximum of two small potential points for four chambers.

Show further technical explanations

Conventional Stirling engines suffer from low power densities – partly due to the extension of the original 90° piston arrangement, which leads to higher friction losses. Heat2Power technology achieves the same power output with a significantly shorter stroke thanks to high compression ratios.

Since lateral forces are completely eliminated from the pistons, they can be designed with a flat profile – guide seals or longitudinal supports are unnecessary. A single piston ring with a small gap is sufficient for each double-acting cylinder – for thermal separation, not for external sealing.

Sealing against gas loss occurs exclusively in the area of the piston rod – with a significantly smaller diameter than the piston itself. This results in only minimal friction losses over a small area.

Furthermore, any potential leaks occur exclusively on the side facing the crankshaft – meaning a maximum of two potential leak points for four cylinder chambers.

Unlike combustion engines, the heat generated by friction is not dissipated via the exhaust gas – it remains in the system and is largely transferred to the working gas.

This creates a positive side effect: The frictional heat indirectly supports the heating process and increases efficiency.

Friction losses can be drastically reduced by using a

Hypocycloid straight-line guidance

![]() .

A classic crank drive generates three to five times more friction loss than a hypocycloid linear guide – depending on speed, lubrication, and size.

.

A classic crank drive generates three to five times more friction loss than a hypocycloid linear guide – depending on speed, lubrication, and size.

For your information: In combustion engines, only about 27 percent of the total energy in the fuel is delivered as useful work via the crankshaft. Approximately 9 percent of the energy is lost as heat through friction within the engine.

(https://www.springerprofessional.de/)

Show further technical explanations regarding the connecting rod ratio λ

If a crankshaft is used instead of a

Hypocycloid straight-line guidance

![]() system, the mechanics can be positively influenced by a large connecting rod ratio λ. The ratio between the length of the connecting rod and the stroke of the engine (connecting rod ratio) significantly affects the dynamics of the piston, i.e., the velocity profile over the stroke. A large connecting rod ratio results in a more uniform piston speed, and thus lower peak piston speeds and accelerations.

system, the mechanics can be positively influenced by a large connecting rod ratio λ. The ratio between the length of the connecting rod and the stroke of the engine (connecting rod ratio) significantly affects the dynamics of the piston, i.e., the velocity profile over the stroke. A large connecting rod ratio results in a more uniform piston speed, and thus lower peak piston speeds and accelerations.

$$\dot{s}(\alpha) \approx \omega \cdot r \cdot \left( \sin(\alpha) + \frac{1}{2\lambda} \cdot \sin(2\alpha) \right)$$

ω = Angular velocity, derived from the rotational speed using ω = 2π · (n/60).

r = Crank radius. 2 x r = piston stroke

α = Crank angle (current angular position of the crank)

λ is the rod ratio, the ratio of connecting rod length to crank radius: λ = l / r. A larger λ means that the piston motion is closer to an ideal sinusoidal curve, resulting in smoother running, lower lateral forces, and therefore less friction.

Comparison of a 2-cylinder machine with other machines

2 revolutions |

Heat2Power-Engine (1 hot+ 1 cold cylinder) Hypocycloid gear |

2-cylinder marine engine (2-stroke diesel) |

Classic Stirling engine (1 hot+ 1 cold cylinder) |

2-cylinder gasoline or diesel engine (4-stroke) |

| Work cycles | 4 | 2 | 2 | 1 |

|

Relative contact pressure Piston rings |

very low | high | high | high |

| Number of sealing/piston rings, friction points |

2 big (piston) + 4 small (piston rod) + 2 sealings + 2 crank pin |

min. 4 big (piston) + 2 linear guidance + 2 crank pin + valve train |

min. 4 big (piston) + 2 crank pin |

min. 4 big (piston) + 2 crank pin + valve train |

| Friction work relative to stroke | 1 | 2.5 ... 3.5 | 2.0 ... 3.0 | 2.0 ... 3.0 |

|

Relative friction loss/ work cycle Assumptions: DMR cylinder / DMR piston rod = 2 ... 3 |

1 | apr. 5.0 ... 7.0 | apr. 4.0 ... 6.0 | apr. 8.0 ... 12.0 |

Further technical explanations for the comparison

The Heat2Power-Engine operates with only two cylinders – an expansion cylinder and a compression cylinder – which are, however, designed to be double-acting. This results in four power strokes every two engine revolutions, whereas, for example, a four-stroke combustion engine only delivers one power stroke every two revolutions.

The friction points are optimized: only two large piston rings are used for a pair of cylinders (instead of four to six), but the sealing takes place at the piston rod – there with significantly smaller diameters.

Furthermore, when using a

Hypocycloid straight-line guidance system

![]() instead of a crankshaft, the friction points of the crosshead axial guide are eliminated.

instead of a crankshaft, the friction points of the crosshead axial guide are eliminated.

Conclusion: The Heat2Power-Engine generates more thermodynamically usable work with less friction – the friction loss per work cycle is only about 10% to 25% compared to classic machines.

High efficiency and energy yield:

- High thermodynamic efficiency due to large temperature difference and high compression.

- No cyclic heating/cooling of components – stable temperature control reduces losses.

- Compression ratio is not limited by fuel properties – compression occurs independently of the fuel type.

- No waste heat via the exhaust gas – heat remains in the system and can be recovered.

- Frictional heat, recovery heat, and radiant heat are utilized effectively – e.g., for combustion air preheating.

- Heat recovery systems can be easily integrated – e.g., through enclosure or recuperators.

- The theoretical Carnot efficiency is almost achieved – thanks to stable process control and a large ΔT.

- Overall efficiency significantly exceeds that of all known heat engines.

Further technical explanations regarding efficiency

The Heat2Power engine achieves exceptionally high efficiency because it eliminates many traditional sources of loss.

The thermodynamic efficiency approaches the Carnot efficiency, which is defined by the temperature difference between the hot and cold sides:

η = 1 – Tcold / Thot

Example:

With Thot = 1100K and Tcold = 300K, the following results:

η ≈ 1 – 300 / 1100 ≈ 0.727 → 72.7 %

Since no cyclic temperature changes occur, high-temperature resistant materials can be used – without cracking or aging.

Recovered heat from the burner environment, piston friction, or radiation is either trapped in the system and fed back into the cycle, or can be used to preheat the combustion air – thus reducing the required burner energy input.

➡ The overall energy yield is therefore significantly higher than with Otto, Diesel or classic Stirling engines.

Environmental friendliness:

- The machine's high efficiency means low energy consumption – less fuel used per kWh.

- Central burner with continuous heating – no explosion, no unstable flame front.

- Use of low-emission burner concepts such as

Flameless Oxidation (FLOX)

,

Poreburner

,

Poreburner  ,

oder

COSTAIR-burner

,

oder

COSTAIR-burner  -technology ispossible.

-technology ispossible. - Fuel-free operation during the power cycle: Energy transfer via heat, not combustion in the cylinder.

- The system can also be operated with industrial waste heat, biogas, or surplus renewable electricity – a wide range of fuel options.

- Ideal for decentralized power generation or storage solutions – for example, with High-Temperature Thermal Storage.

Further technical explanations

The Heat2Power-Engine does not operate with explosive combustion like diesel engines, but with continuous heating via a central burner. As a result, depending on the system, there are no flame fronts or pressure peaks, and emissions are significantly reduced.

Burner systems such as FLOX (flameless oxidation), porous burners, or jet burners can be installed – these operate with particularly low NOx emissions and enable low pollutant emissions even without exhaust aftertreatment.

Costs

- The Heat2Power-Engine is a robust, durable machine with a simple design that requires little maintenance and spare parts.

- The system consists largely of piping and standard purchased components.

- No complex geometries – most components are rotationally symmetrical or flat.

- Modular design facilitates series production, spare parts replacement, and scaling.

- Low-friction design reduces ongoing operating costs and maintenance effort, and extends maintenance intervals and service life.

- High efficiency and recovery systems reduce fuel consumption.

Further technical explanations regarding the cost structure

The Heat2Power-Engine does away with many cost-driving components of classic machines: no valve trains, no cylinder heads with complex controls, no lubrication circuits.

The components are mostly rotationally symmetrical and can be manufactured cost-effectively on CNC machines.

Thanks to their modular design, cylinder assemblies can be easily replaced – ideal for maintenance or series production.

Heat exchangers, piping, sensors, etc. are standard purchased parts.

➡ Overall, the ratio of investment to performance is significantly lower than that of classic engines – while at the same time offering lower running costs.

Contact + License Inquiry

- Dipl. Ing. Thomas Seidenschnur

- info@heat2power.com