]

]

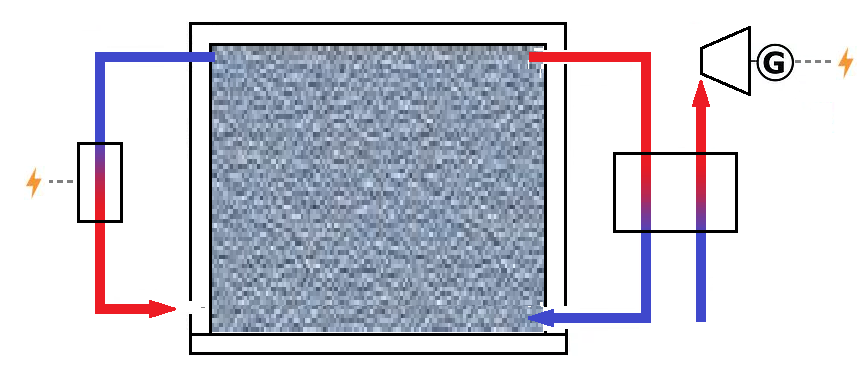

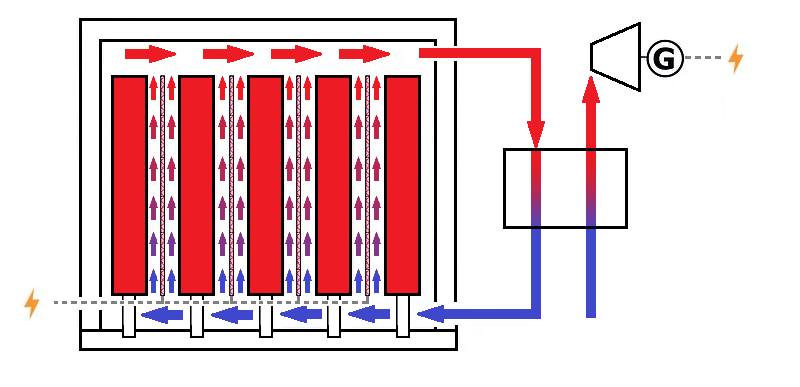

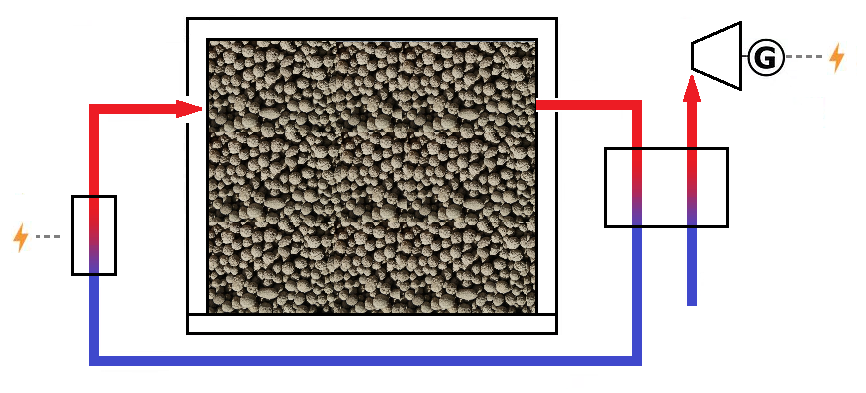

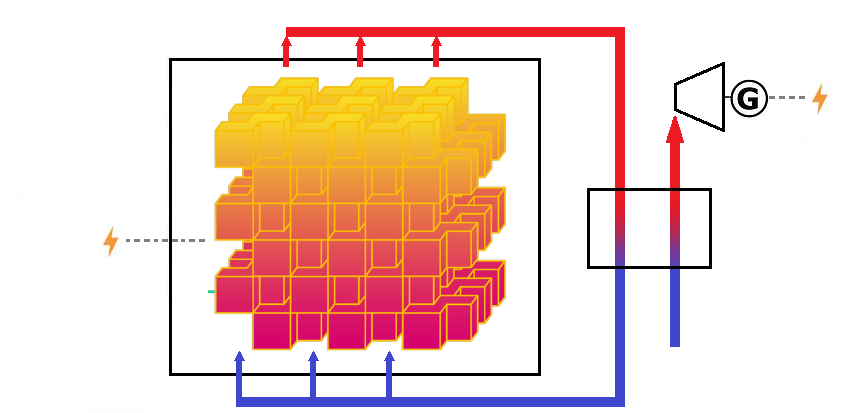

Manufacturer information: The stored heat can be used to generate 1.5 MW of electrical energy over a period of 24 hours via a steam turbine.

Their main common mistake: First select the storage material, then determine the layout of the system

Note: Subsequent turbines require at least 300°C to operate. Only heat provided by the storage between 300°C and Tmax can be used to generate electricity. Heat below 300°C can only be used as process heat. The usable proportion of stored heat is therefore small, and the efficiencies of existing technologies are generally poor. This is why this technology is not yet widely used.

The claimed efficiencies of the actual suppliers refer to electricity + heat, which is just a marketing trick. In addition, these tricky calculations do not take into account that the heat supply is cyclical and not continuous.